How AI Enhances Industrial Supply Chain Transparency

How AI Enhances Industrial Supply Chain Transparency

Through increased transparency, enhanced operational efficiency, and the ability to make proactive decisions, artificial intelligence (AI) is transforming the supply chains of industrial companies. Supply chains in the modern era are complicated and difficult to monitor because they involve a number of different suppliers, manufacturers, logistics providers, and distributors. Companies are able to monitor every stage of the supply chain, identify potential hazards, streamline processes, and guarantee compliance with regulations thanks to artificial intelligence technologies such as machine learning, predictive analytics, and natural language processing. By increasing transparency, one may improve reliability, decrease the number of disruptions to operational processes, and strengthen confidence with both partners and consumers.

Monitoring and Data Collection Carried Out in Real Time

With the help of artificial intelligence, supply chain transparency may be improved by monitoring inventory, shipments, and production processes in real time. Data is collected throughout the supply chain via sensors, RFID tags, and Internet of Things devices, which then feeds artificial intelligence algorithms that process information instantaneously. This makes it possible for businesses to see the movement of items, identify delays, and determine anomalies between the timetables that were predicted and those that were really delivered. When businesses have access to real-time insights, they are better able to maintain operational continuity, increase communication with stakeholders, and respond more rapidly to disturbances.

Applying Predictive Analytics to the Management of Risk

Industrial supply chains are susceptible to a wide variety of hazards, such as delays caused by suppliers, problems with transportation, and interruptions caused by geopolitical events. Predictive analytics is utilized by artificial intelligence in order to evaluate these risks by examining historical data, trends in the industry, and external factors. Companies have the ability to take preventative steps, such as modifying inventory levels, rerouting shipments, or obtaining alternative suppliers, if they are able to anticipate future bottlenecks or delays in their operations. The provision of a clear awareness of prospective vulnerabilities and the associated mitigation techniques is one way in which predictive insights contribute to increased openness.

Evaluating the Performance of the Supplier

Through the monitoring of parameters like as delivery times, quality consistency, and compliance with standards, artificial intelligence makes it possible to conduct a comprehensive review of the performance of suppliers. Algorithms that learn through machine learning examine data from suppliers over a period of time, recognizing patterns and highlighting providers that are not doing well. Because of this transparency, businesses are able to make educated decisions about the selection of suppliers, the negotiation of contracts, and the formation of long-term partnerships. Strengthening responsibility and encouraging adherence to ethical and operational standards are two additional benefits that come from improved supplier oversight.

Improving the Planning of Production and Inventory Management

Artificial intelligence-driven inventory and production optimization are beneficial to supply chains that are transparent. Artificial intelligence is able to make recommendations regarding appropriate inventory levels and production plans by examining demand estimates, past sales, and production schedules. In order to guarantee that raw materials and finished items are available at the precise moment they are required, businesses can avoid overstocking or stockouts. The reduction of operational inefficiencies and the facilitation of smoother coordination across various sites are both outcomes of increased transparency in production and inventory data.

Improving Logistical Operations and Tracking of Shipments

Logistics platforms that are powered by artificial intelligence achieve greater transparency by tracking shipments and transportation in real time. For the purpose of providing accurate delivery predictions, algorithms examine factors such as traffic conditions, weather trends, and the effectiveness of routes. Artificial intelligence systems that are more advanced are also able to detect anomalies, such as delays, lost shipments, or damaged items, and swiftly notify stakeholders. When businesses have improved visibility into their transportation operations, they are better able to guarantee punctual delivery and further increase their consumers’ trust.

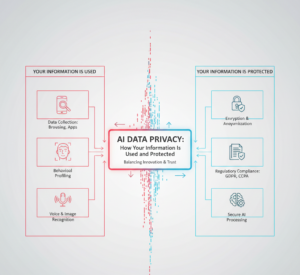

Compliance with Regulations and Openness to the Public

Certain industries are subject to rigorous laws concerning the influence they have on the environment, labor practices, and product safety. Compliance may be maintained with the assistance of artificial intelligence by monitoring activity along the supply chain, recording operations, and automatically generating reports. Companies are able to demonstrate that they are in compliance with regulations and standards when they maintain transparent records of the sourcing of their suppliers, production procedures, and shipment history. This eliminates the possibility of incurring legal penalties and improves the company’s reputation with customers and regulatory agencies.

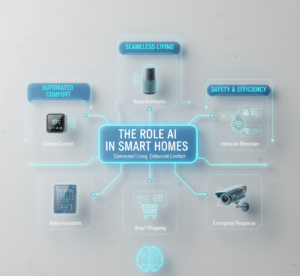

Integrating Intelligent Supply Chain Ecosystems into the System

AI is able to have the most impact when it is linked with more comprehensive smart supply chain systems. An ecosystem that is transparent from beginning to end is created by combining artificial intelligence with Internet of Things devices, cloud platforms, and advanced analytics tools. By integrating these systems, it is possible to maintain continuous monitoring, make decisions quickly, and communicate without interruption throughout the supply chain. Enterprises are able to acquire a comprehensive perspective of their operations, which enables them to enhance their performance, react rapidly to changes, and maintain transparency with their partners.

Adaptive learning and continuous improvement are two concepts.

Artificial intelligence algorithms, which are always learning from new supply chain data, improve the accuracy of their predictions and the operational recommendations they provide over time. The ability of the system to adapt to shifting market conditions, fluctuations in the performance of suppliers, and unexpected interruptions is made possible by adaptive learning processes. A self-optimizing supply chain that is transparent, resilient, and efficient in the face of dynamic industrial conditions is created as a result of this throughout the course of time.

Artificial intelligence improves the transparency of industrial supply chains by enabling real-time monitoring, predictive risk management, evaluation of suppliers, and optimization of logistics resources. Integration with intelligent supply chain ecosystems and ongoing adaptive learning are two methods that further increase operational efficiency, regulatory compliance, and reliability. Artificial intelligence gives businesses the ability to make educated decisions, reduce risks, and develop trust with partners and customers while preserving a competitive advantage. This is accomplished by offering a clear and data-driven view of the actions that occur along the supply chain.