What Artificial Intelligence Can Do for Supply Chain Management and Logistics

What Artificial Intelligence Can Do for Supply Chain Management and Logistics

The complexity of global supply chains has always been there, but the last few years have brought to light the fact that they may be quite fragile. Companies have been put under pressure to reevaluate their logistics management practices as a result of disruptions brought on by the pandemic, geopolitical tensions, decreased labor availability, and increased consumer demand. Artificial intelligence (AI) is becoming an increasingly popular solution for enterprises interested in addressing these difficulties. Artificial intelligence is changing supply chain management and logistics into systems that are smarter, more robust, and more cost-effective. This is being accomplished by processing huge volumes of data in real time.

Why Artificial Intelligence Is Necessary for Supply Chain Management

In traditional supply chains, demand forecasting and inventory management are often accomplished via the use of historical data and hands-on techniques. Despite the fact that this strategy is effective under stable circumstances, it is not suitable for the rapidly changing world of today. Artificial intelligence offers a dynamic alternative due to its ability to evaluate live data from numerous sources, forecast outcomes, and recommend proactive methods. This enables enterprises to respond rapidly to changes in their environment.

1. Applications of Artificial Intelligence within the Supply Chain and Logistics 1. Demand Forecasting

Historical sales, seasonal patterns, and external influences like as weather, market fluctuations, or world events are subjects of analysis by artificial intelligence. Because of this, businesses are able to estimate demand with a far higher degree of precision, which helps them avoid stockouts and excess production.

2. The optimization of the inventory

It is challenging to keep the amount of inventory in the appropriate balance. Systems that are powered by artificial intelligence have the ability to establish ideal stock levels, reduce holding costs, and avoid shortages, which ultimately leads to more effective warehouse management.

3. Optimization of the Route

By taking into account factors such as traffic, fuel usage, and weather conditions, artificial intelligence assists logistics companies in determining the most efficient and cost-effective delivery routes. This leads to reduced expenses associated with transportation as well as a reduction in delivery times.

4. Predictive Maintenance for Vehicles and Material Handling Equipment

Artificial intelligence has the ability to identify malfunctions before they occur by monitoring data from trucks, ships, and warehouse gear. This helps to reduce downtime and minimize expensive interruptions for businesses.

5. Risk Management throughout the Supply Chain

In order to identify possible disruptions, artificial intelligence systems monitor worldwide news, weather reports, and geopolitical events. Companies are have the opportunity to make adjustments to their sourcing, reroute their shipments, or obtain backup sources.

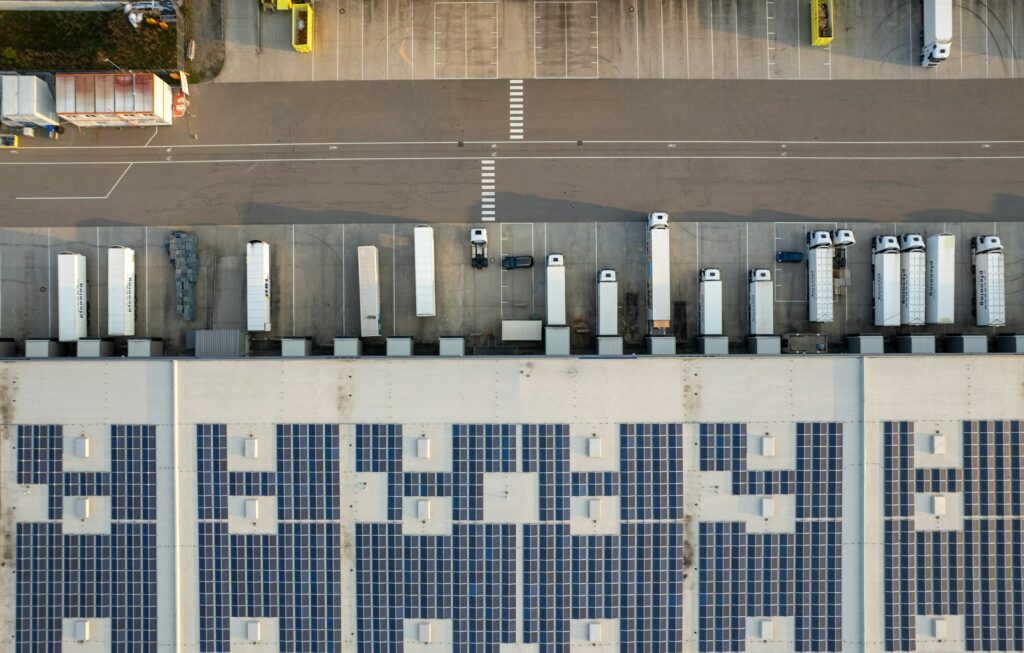

6. Automated Warehouse Procedures

Robots and automated systems that are driven by artificial intelligence are able to handle picking, packaging, and sorting with more efficiency, particularly during peak demand seasons like as the holidays.

7. Improvements to the Experience of the Customer

Through the use of proactive alerts and real-time delivery monitoring, artificial intelligence (AI) enhances transparency for consumers, hence fostering trust and happiness.

8. Uses of Artificial Intelligence in Supply Chain and Logistics

- The optimization of routes, the reduction of downtime, and the improvement of demand planning all contribute to improved cost management.

- Increased Productivity: Automated procedures accelerate activities, hence minimizing the number of mistakes and delays that occur.

- Predictive analytics may assist businesses in preparing for and adapting to disruptions, which is a source of resilience.

- When it comes to sustainability, artificial intelligence helps businesses adopt greener practices, optimizes fuel consumption, and lowers waste.

- Increased Customer Satisfaction: Deliveries that are both quicker and more dependable contribute to a stronger brand reputation.

Actual-World Illustrations

- Through the use of artificial intelligence-driven robots in warehouses and sophisticated algorithms for anticipating what goods consumers will purchase, Amazon is able to deliver orders more quickly.

- By using an artificial intelligence-driven route optimization technology known as ORION, UPS is able to save millions of gallons of gasoline each year.

- For the purpose of enhancing demand forecasting, route planning, and warehouse automation throughout its worldwide network, DHL has integrated artificial intelligence.

- Using artificial intelligence, Maersk is able to forecast delays in shipments and improve port operations.

The Obstacles for the Implementation of AI in Supply Chain

Although the advantages are substantial, there are still problems to be faced:

- High Implementation Costs: On the other hand, smaller enterprises can have difficulty making initial expenditures.

- Inaccurate or inadequate data may have a negative impact on the performance of artificial intelligences.

- Connected systems are susceptible to data breaches and assaults, which are both risks associated with cybersecurity.

- Adaptation of the Workforce: In order for employees to properly collaborate with AI systems, they need training.

The Prospects for Artificial Intelligence in the Supply Chain and Logistics Industry

The emergence of smart supply chains, in which every step in the process is linked and optimized, is largely dependent on artificial intelligence (AI). Most probable, the future will witness:

- Autonomous delivery vehicles, including drones and self-driving trucks, are powered by artificial intelligence.

- Blockchain technology used with artificial intelligence to make transactions more safe and transparent.

- AI is used to monitor items from the raw ingredients to the final consumer, which is referred to as end-to-end visibility.

- Circular supply chains, in which artificial intelligence optimizes the recycling and reuse of commodities for better environmental impact.

Increasing their intelligence, efficiency, and resilience, supply chain management and logistics are being reimagined as a result of the use of artificial intelligence. When it comes to reducing costs, improving customer experiences, and preparing for unanticipated disruptions, artificial intelligence enables organizations to do anything from anticipating demand to optimizing delivery routes.

Artificial intelligence (AI) is no longer a luxury for businesses that want to survive in the current global economy; rather, it is becoming a need for businesses in a world where agility and dependability are of the utmost importance.